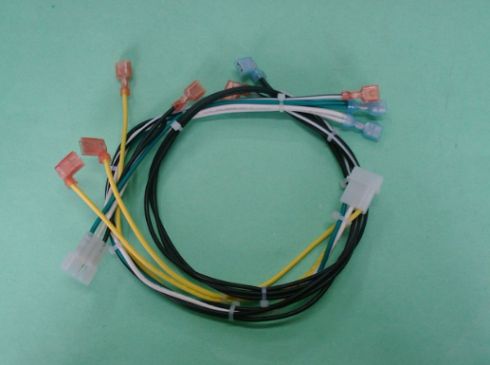

Everything You Need to Know About Custom Wire Harnesses

Cable assembly manufacturing has developed into an immense industry with huge requests of the modern Cable assembly and fixture items over the commercial enterprises. In the previous couple of decades, it achieved extraordinary development to a great extent on account of the expanding interest for high end machines. In today’s world, high class hardware products, mess free innovation and minimal size is the essential parameter and without cable assembly this can’t be conceivable. In spite of the fact that standard cable assembly products are accessible to meet the prerequisites of various commercial ventures, custom wiring harness enjoys steady rise in fame as with their particular needs can be tended to and greatest yield can be ensured.

Favorable circumstances of custom wire harness in various businesses

Commercial ventures that especially require long extensions of wire like the car, aviation and flight, electrical apparatus, renewable energy and telecom, developed more interest towards the wiring harness in the previous couple of decades. Keeping in mind the end goal to run the vehicles and machines all the more effectively, they have to deal with the cables in a sorted out a way. The key advantage of utilizing the wiring harness is that without much of a stretch you maintain a strategic distance from clustered wiring inside the machines and can put them in uniquely crafted sleeves, offering more clarity and maneuvering.

In automobiles, hardware supplies, planes, rail and transport frameworks and restorative types of equipment’s the requirement of miles’ length of cable and wiring is basic, however setting them inside the vehicle or apparatus to accompany most extreme yield is an equivalent concern. Without a cable harness, the free wires are liable to devour a lot of space and can add to the complexities and take a lot of space required by the machine. Introducing a wire harness is less complex and tedious, contrasted with establishment of loose wires inside a framework. The usage of wire harness helped machines turn out to be more conservative in size, simple for working, establishment and smooth run requiring less upkeep.

Options in wiring harnesses

With respect to choosing among various sorts of wiring harnesses any of the two broad classes makers need to focus on, separately as standard wire harness and custom wire harness. For general hardware without requiring any exceptional application standard wire hardness can be fitting. Be that as it may, for particular and custom uses for the most part custom wiring harnesses are required. Custom wire harnesses are requested when it is felt that the particular prerequisites of the machine can’t be met with the standard kind of wire harness.

Commercial enterprises that require custom wire harnesses

Custom harnesses are especially well known in the car, aeronautics, rail and open transport frameworks, therapeutic types of gear and electrical building commercial ventures as a result of their development and one of a kind outlines in apparatus parts and supplies. Normally, these businesses needn’t bother with a common sort of wiring and rather they require more hand crafted wiring solutions for particular purposes. For example, military flying offering the bleeding edge aeronautics innovative in their developing battle planes dependably needing custom wire harnesses for guaranteeing the ideal yield from the design of their types of gear and vehicles.

In the automobile industry likewise we can see the rapid growth of vehicle designs that are emerging each year. With new designs of traveler autos, trucks, sport vehicles, commercial vehicles always coming up, custom wiring and cabling arrangements are an ideal fit for their purpose and configuration components. The expanding variety being handled in R&D labs of automobile makers, adds to this custom wire harness necessity.

New and advancing designs of apparatus additionally require the custom wiring most to fit the particular prerequisites. Hardware parts and types of gear are advancing with new innovation and more requests of conservativeness and minimum utilization of space. Normally, while minimization and diminished impressions turned into a rule for cutting edge apparatus units nowadays, there is a vast increment in the requests of the particular and custom wire harnesses that fits their size, shape, reason and innovation.

At long last, with regards to picking your wire harness manufacturer to sustain all your particular wiring needs, you have to consider a couple of possibilities. Clearly, an organization with the solid subjective goal ought to be contracted as before customizing needs material and assembling quality ought to be the primary thing to search for. Also, it is critical to see the assortment of wire harness that the organization is specific with. You ought to get a custom harness that is made with in depth contemplation of your particular needs and that can guarantee ideal electrical result.

Leave a Reply